Rapid prototyping – the name is almost a program. Literally translated, rapid prototyping means fast model building. This term acts as a generic term for the different processes for the rapid production of sample components or groups; straight manufacturing methods based on CNC machines are an integral part of this rapid prototyping technology. The term has also established itself as the umbrella term for numerous 3D printing applications. Rapid prototyping is created by prototype development to create physical models from three-dimensional CAD design data (Computer Aided Design, CAD) within a short period of time. Thanks to rapid prototyping Advantages, companies now have the opportunity to efficiently and quickly translate innovative ideas or visions into finished end products.

Automated Process

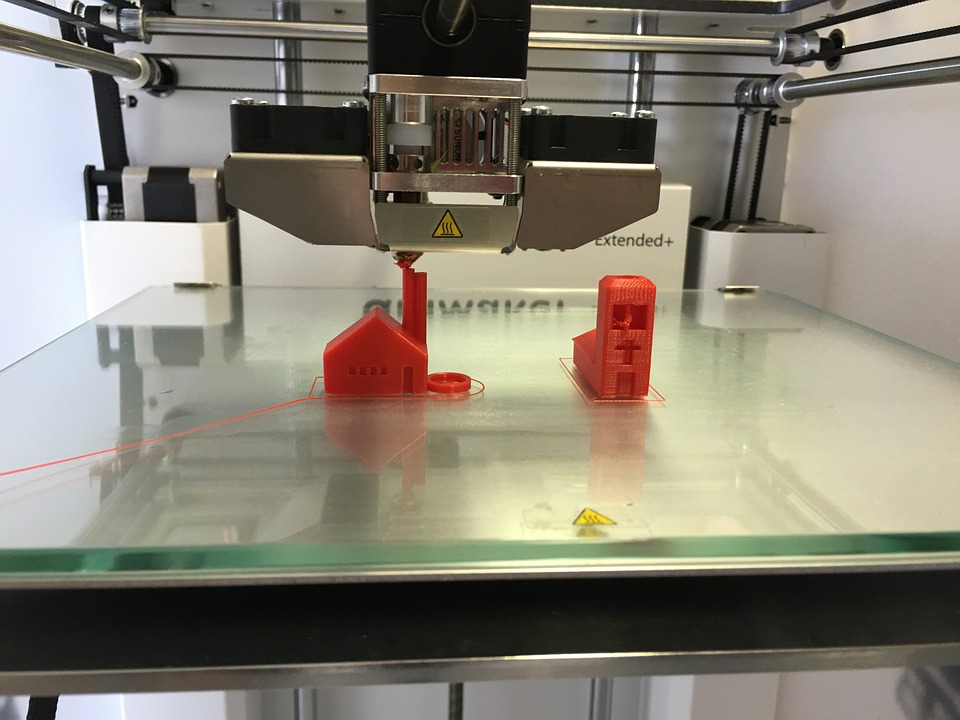

Rapid prototyping, also commonly known as 3D printing, involves additive manufacturing technology. The aim is to convert existing CAD data into workpieces quickly and directly in an automated process. At best, this is done without any manual detours, actions, and forms. A corresponding stratified structure of a form-neutral or even informal material is supported by the use of chemical and physical effects.

At the beginning of the actual process, a virtual design is then designed using CAD software or a related modeling program. In the following, the 3D printer then reads the corresponding data from the respective CAD drawing. The printer explicitly layers of different materials; usually these layers are made of powder, liquid or plate material.

Through this layered structure, the physical model emerges, as it were, from a multitude of cross-sections. In order to produce the final shape, the virtual cross-sections or the individual layers are then automatically connected to each other. Processes of this kind, which have characterized the concept of rapid prototyping since the 1980s, are usually so-called original molding processes.

Better Than Conventional Methods

To ensure permanent and error-free translation or communication between the 3D prototyping device used and the CAD software, a standard interface created in the STL file format is used. In this case, the shape of an assembly or a component with triangular surfaces is created or reproduced in this STL file format. With this technique, models, prototypes or tools can be made much better than with conventional methods.

However, no generalized times can be mentioned because the production time depends on several factors. Thus, there are often significant differences between the different manufacturing processes, between the size and the respective complexity of the model or the object, as well as between the printability and quality of the existing 3D model.

There was a time when people used paper, pencil and a lot of time calculations to design a prototype. These days, with advances in technology, companies have evolved into a prototype design with the use of (CAD), rapid prototyping. Most of the advantages have to do with speed, as rapid prototyping allows designers to produce more accurate mock-up techniques at a faster pace. But no prototyping system is perfect, and rapid prototyping is no exception, as it can lead to endless revisions that are sometimes not cost effective. Below we shall more advantages you could be on the lookout for, continue reading.

Fast Recovery

In the product development phase of any product designed, the more the product is ready to be marketed, the better. Rapid Prototyping provides product designers with faster ways to create, calculate, and recalibrate product samples. These prototypes are then used to test consumer response and technical feasibility, as development progresses. This allows for a more accurate final product and ready to cook to build earlier.

More Accurate Calculations

There are many stages of revisions in any prototyping system, but rapid prototyping ultimately leads to a more technical final project, rather than a possibly erroneous hand-drawn mockup. Each phase of the design, creation, and the results of the revision in a more accurate model that will end up being the final product! The calculations used to measure the hand and instruments, are now calibrated with the accuracy and efficiency of computer-aided design, making it less likely that definitive prototypes will be falsified.

Customizing Designs

The greatest promising advantage of rapid prototyping is the power to create custom-made items according to the specific requirement. It takes absolutely no special gear or perhaps processes to apply adaptations in the product. A little alteration in the CAD model, as well as the entire procedure remains the very same. For producers, this really is highly beneficial because it provides a connected experience for the client with the item they obtain.

Best Suited For Small Products

It is easier to use rapid prototyping to develop a small item or a component of a larger item than it is to recreate an item on a large scale. The reason is simple: rapid prototyping goes through the stage-by-stage development of a prototype, removing the old that revisions aspire to perfection. For a large-scale item, it may not be profitable to create. In addition, the larger the product, the more vivid access memory (RAM) it takes to design. A computer may simply not have the RAM capability to produce something big.

Price Of Rapid Prototyping Is Reasonable

The cost involved in creating and rejecting many versions of a prototype varies depending on the size of the item, the cost of the materials being manufactured, and the number of revisions needed to reach the final version ready for production. For this reason, the cost associated with prototyping can be very reasonable depending on the actual product being developed. Like any other form of product development, if the projected sales figures and the predictable revenue do not cover the cost of the development process, there is always the possibility that a project could be terminated.

Conclusion

In some cases, rapid prototyping systems can be used to produce 3D models in just a few hours; As a rule, the creation of a very complex object takes no longer than just a few days. This explicitly high production speed allows companies to use both models and prototypes more frequently. Thanks to the objects generated by the procedure, all functionalities can be excellently checked.